The need for bleed

The conversation normally starts with the question “Just about to send a job in for CD manufacturing, what’s you’re turnaround?”, the answer is “about 14 – 16 days”, then the dreaded silence followed by “It’s just we have a set a release date 12 days from today”. The race is on, in this situation every hour counts, and delays can result in missed deadlines. The most common reason for delays in turnaround is having to get artwork re-supplied, and in many cases it is artwork that been supplied with no or too little Bleed.

If your scratching your head and asking yourself “what is bleed?”, then you’re not alone, it’s a bit like the offside rule, you either get it, or you don’t, but thankfully it’s much easier to explain. Bleed is a printing term that applies to all of the DVD & CD booklets, digi-packs, card wallets and record sleeves that we print. Just so we are all singing from the same hymn sheet I will use a CD booklet as an example, but the principles apply to all of the packaging products that we print.

The sheet of paper that is a CD booklet did not start life the size it is, it was once on a much larger sheet of paper that contained other CD booklets being printed at the same time. The reason for doing this is the “economy of scale” as running several jobs together on a large press brings down the cost of printing.

When the job has finished printing the next stage is to cut the large sheet down into individual CD booklets, this is a process known as “trimming”, and is done by machine. As with most mechanical processes we need to allow for a tolerance, and in trimming this tolerance is 1.5 millimetres (mm). This means that we have to allow for movement of the paper in the trimming process by up to 1.5 mm, in reality the machines are more accurate than this.

It is the allowance of this movement when trimming that brings us to bleed. Our CD booklet measures 120mm in height and 241mm in width when trimmed, and many people when designing their artwork supply it to us at exactly this size. This is where the problems start.

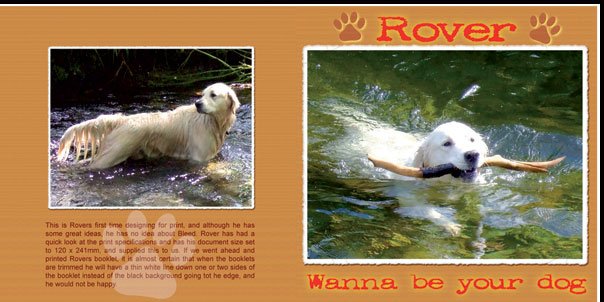

Lets start with an imaginary client who is producing his first CD, his name is Rover and he is a Golden Retriever, actually he’s my dog, and the only photos I have to hand that are not subject to copyright are pictures of him. So Rover has finally got around to releasing his homage to Iggy Pop with his own version of “Wanna be your dog”.

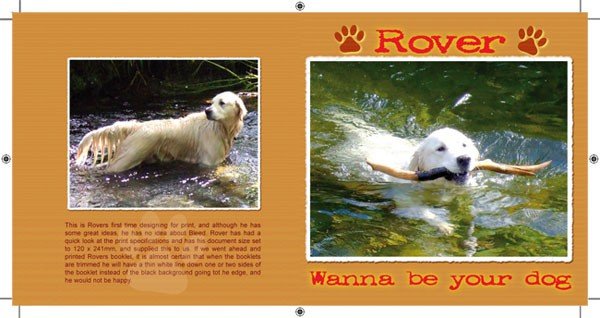

This is Rovers first time designing for print, and although he has some great ideas, he has no idea about Bleed. Rover has had a quick look at the print specifications and has his document size set to 120 x 241mm, and supplied this to us. If we went ahead and printed Rovers booklet, it is almost certain that when the booklets are trimmed he will have a thin white line down one or two sides of the booklet instead of the background going to the edge, and he would not be happy.

What Rover should have done is added bleed, this is extra background that extends beyond the print area, in most cases this should be 3mm on ALL sides. So with the correct bleed added Rover’s booklet will measure 126mm (additional 3mm top and bottom) and 247mm (additional 3mm left and right sides). This does not only apply to solid backgrounds, it should be applied to any part of the artwork that goes to the very edge of the page, that includes things like photos or logos.

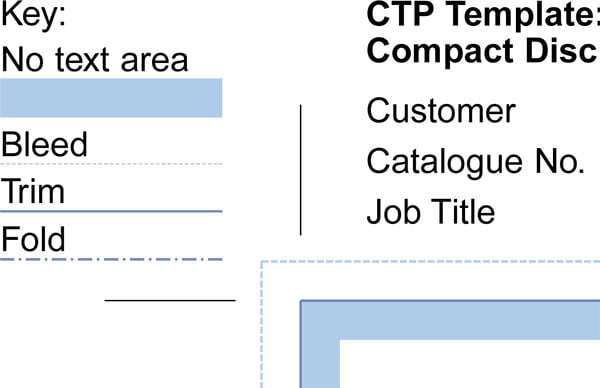

To make life a a little easier all of our PDF templates clearly show this bleed area as a blue dotted line, all you have to do is extend the artwork out to this area and you will be fine. It is also worth mentioning that we do not recommend having text or other important information to close to the edge of the page, as any movement in trimming may lead to this being cut off when trimmed, we recommend not placing text closer than 3mm to the edge. Again our PDF templates clearly show this area as a thick blue line, just keep the important things inside of this area.

I hope after reading this that you understand the reason for bleed and how to supply artwork . However if you’re still confused or disagree with anything, feel free to comment.

Cheers

Kev

Pure Music