Using the correct colour space for CD Printing

If you are designing your first album cover for CD manufacturing, the chances are you will have never heard of the terms RGB and CMYK “colour spaces” when describing colour. But this can be a cause of great frustration for those who have never dealt with professional printing. This is not only something those who are embarking on their first CD pressing should be concerned with, but anyone who is working with any type of professional printing. So what does RGB and CMYK mean and how does it affect your design?

I can pretty much guarantee that you that you are reading this blog on a display device that renders colour in RGB format, this stands for Red, Green and Blue. These are the three primary colours that nearly all display devices use to transmit colours to our eyes. This is a great system as it is possible to re-create a large range of the colour spectrum that our eyes can perceive with just three colours.

However Red, Green & Blue are not suitable for interpreting colours using ink, for instance when printing a CD booklet. The preferred method for printing with ink uses four colours, Cyan, Magenta, Yellow & BlacK (for some reason the letter K is used for Black, never really been given a definitive reason why). Now you may be thinking with these four colours we can produce a larger range of the colour spectrum than with the inferior three colours used for RGB display devices. Sadly not.

However Red, Green & Blue are not suitable for interpreting colours using ink, for instance when printing a CD booklet. The preferred method for printing with ink uses four colours, Cyan, Magenta, Yellow & BlacK (for some reason the letter K is used for Black, never really been given a definitive reason why). Now you may be thinking with these four colours we can produce a larger range of the colour spectrum than with the inferior three colours used for RGB display devices. Sadly not.

But how can three colours re-create more colours than four? Well I will give you a clue….. “It surrounds us, penetrates us, and binds the galaxy together” OK it’s not the force, but it is light. The screen you are using has a white light source behind it that transmits the colours to your eyes. This white back-light is what gives the the RGB colour space the advantage over the four colours used to print CD booklets.

By contrast paper does not have a back light source to help project colours. I have devised a simple experiment to prove this point. Take a laptop and a CD booklet into a dark room and see which you can read with ease. You will notice that you can’t see the images in the magazine that easily, but the laptop image is bursting with colour. The reason for this is that when viewing print we rely on the ambient light around us reflecting off the ink and into our eyes, not having a light source from the paper is the reason why we cant print using RGB.

So what’s the solution? Well I am currently working on a process that involves weaving white-light producing nano bots, that have an infinite self sustaining supply of power, into paper and card. However if I am honest progress is slow, so until then we will have to rely on printing using CMYK colour, and that involves certain constraints.

So by now you will be wondering what does this mean in real terms and how does it affect your design. Basically this means that not all of the colours you can see on screen can be reproduced accurately in print. Knowing this limitation will help avoid disappointment when you get your job back form the printers and the colours look different to that expected. It will also help if you set your design software to work in the correct colour mode for professional print.

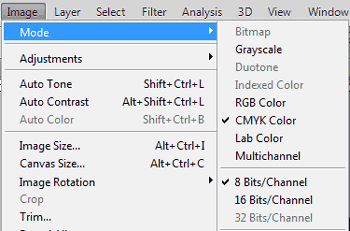

Design software that is used for print artwork, as opposed web design, has many colour modes / spaces that you can work in, see the image on the right that shows the list of colour modes for Photoshop. It is important that for print we are working in CMYK, as this will give us a much closer representation of how the screen colours will appear in print. It is important to note that digital cameras, scanners and most images you will find on the web are in RGB mode, so we will need to convert these to CMYK by changing the colour mode.

Design software that is used for print artwork, as opposed web design, has many colour modes / spaces that you can work in, see the image on the right that shows the list of colour modes for Photoshop. It is important that for print we are working in CMYK, as this will give us a much closer representation of how the screen colours will appear in print. It is important to note that digital cameras, scanners and most images you will find on the web are in RGB mode, so we will need to convert these to CMYK by changing the colour mode.

When changing from RGB to CMYK colour you may notice a significant change in some of the colours. This is particularly noticeable for very bright oranges, blues, greens and reds. To give you an example see the image below, the one on the left is in RGB, the one on the right is the same image converted to CMYK.

As you can see some of these colours have changed , and some very significantly, and to be honest there is not a great deal we can do about this. However it is better to understand this form at the outset rather than tweak your colours in RGB to create those real vivid greens only to find out later that we can’t produce the same colours using CMYK inks.

You may be thinking, well I will send my printers RGB files, and maybe they won’t notice and the colours won’t change that much. Well they will know if your files contain RGB images, it is one of the first things that is checked. Your printer might reject the files and ask you to resubmit as CMYK, or they will convert them to CMYK their end, with the possibility of disappointing colour reproduction.

We have to learn to work within the confines of what it is possible to reproduce with inks. But don’t despair, look at the printed material you have around you. It is not difficult to create really vibrant designs with ink, it just takes a little care.

Now some of those who are used to dealing with print might be saying, “but why not use Pantone colours!”, and you would be right. However if you are familiar with using Pantone colours I am surprised you have read this far, as you will already know the difference between RGB and CMYK and the costs involved in adding additional colours to the press. For the novice adding another layer of complexity is probably not an option. But I have planned a future post about Pantone colours.

That is the difference between CMYK and RGB images,please remember to check that you are working in correct colour mode when designing for print. One final word of warning, working in CMYK is only one battle in the war of achieving colour consistency from screen to print. But look out for further posts when I will cover other aspects of getting the desired colour on you final prints.

I hope you have enjoyed this post,and please feel free to add anything or ask any questions in the comments below.

Cheers

Kev Pure